According to the “Notice of the Office of the Henan Provincial Department of Industry and Information Technology on Organizing the Implementation of the 2025 National 5G Factory List Project”, after review by enterprises, cities, experts and public announcement, the “YTO Diesel Engine 5G Smart Factory” project applied by YTO (Luoyang) Diesel Engine Co., Ltd. was selected as Henan Province’s 5G Fully Connected Factory in 2025, becoming a benchmark for the industry’s intelligent transformation.

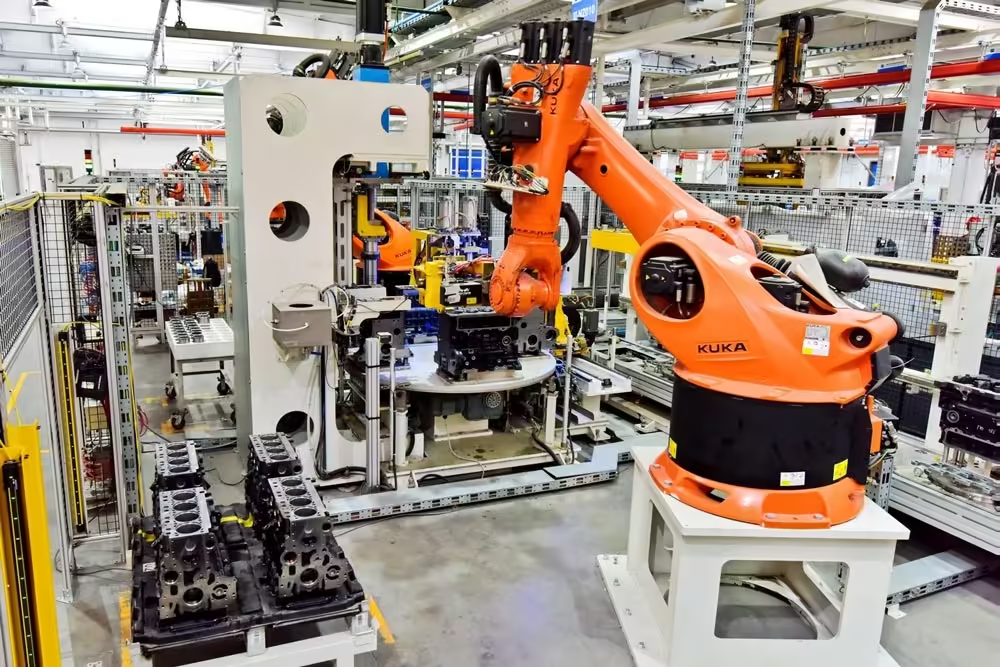

Entering the “YTO Diesel Engine 5G Fully Connected Factory” is like stepping into the model room of the future industry.

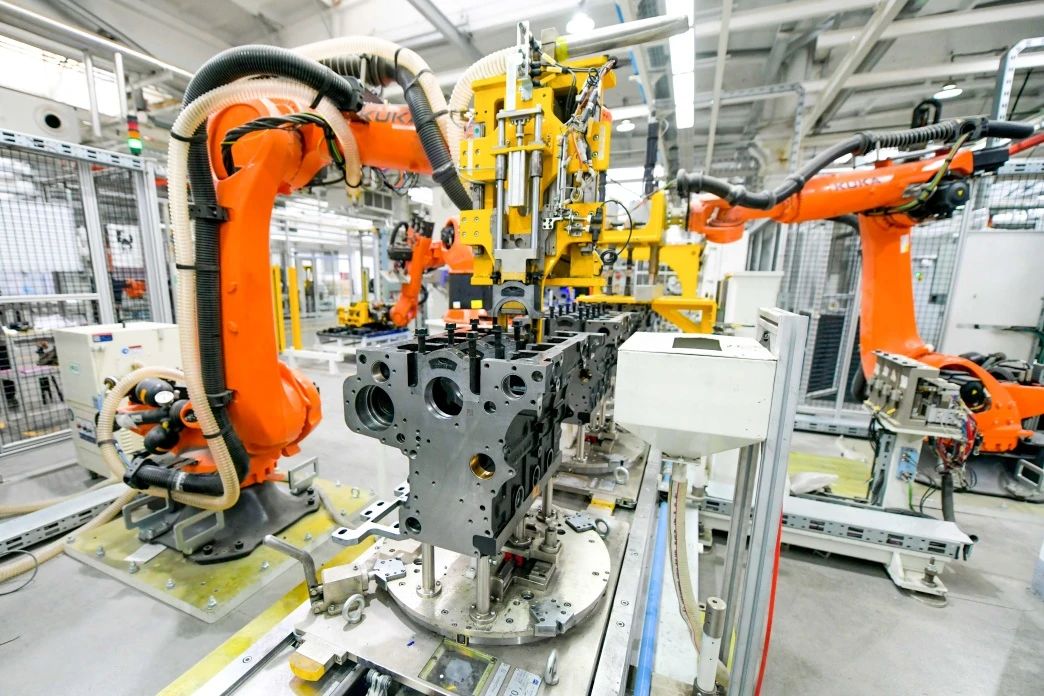

On the production line, industrial robots and intelligent equipment work closely together to achieve high-speed interconnection and real-time data transmission through 5G networks.

From machining to assembly, from parts entering the factory to finished products coming off the line, every link is accurate and efficient.

With the continuous maturity and widespread application of technologies such as 5G, the Internet of Things, and artificial intelligence, YTO (Luoyang) Diesel Engine Co., Ltd. has achieved a full-scale upgrade of production processes and management methods by introducing digital technologies.

Intelligent upgrades run through every link of the factory. The manufacturing process introduces technologies such as modular island collaborative workstations, intelligent error prevention systems using machine vision technology, and intelligent automatic equipment program formulas. 5G+AI industrial visual quality inspection equipment conducts all-round inspections on products, greatly improving inspection efficiency, production efficiency, and product quality consistency. The intelligent vertical warehouse is equipped with AGV, SPS catering and sky corridors, and an intelligent warehouse management system. The on-time delivery rate of parts reaches 100%, and the transportation efficiency is improved by 35%.

The “YTO Diesel Engine 5G Fully Connected Factory” has not only achieved leapfrog development itself, but also created significant social benefits. It has promoted the intelligent upgrading and green transformation of the industry, and provided a transformation model for reference for traditional manufacturing; intelligent production has forced workers to upgrade their skills and cultivated a large number of compound talents; the supply chain management system has driven the coordinated development of upstream and downstream and promoted regional economic growth.

In the future, YTO (Luoyang) Diesel Engine Co., Ltd. will continue to rely on new technologies, deepen its roots in the field of intelligent manufacturing, continue to explore and innovate, inject new impetus into the development of the industry, and lead the equipment manufacturing industry to a higher peak.